How Does Power Steering Work?

Working Of Power Steering

First Inspect PowerSteering?

To inspect your power steering pump:

Check your pump's fluid level.

Check the belt's tension.

Check the seals between the pump and the pulley for leaks.

Also look between the return and pressure hoses for leaks.

Listen for whining or squeaking. This may indicate that the pump needs to be replaced or to have air bled from it.

Check for fluid leaks on the steering gear box or on the rack and pinion.

On older vehicles, check the power cylinder control valve and pressure hoses for leaks.

Some vehicles have an external fluid cooler, if your vehicle has one, inspect it for leaks.

There are basically two styles of vehicle steering systems, rack and pinion and worm gear box. Rack and pinion steering is one of the oldest types of steering systems and is still used today. Inside the rack body a flat rack gear moves in a linear direction driven by a circular gear called a pinion. The steering wheel is connected to the pinion gear (shaft).

Rack and Pinion Steering

The rack gear is connected to an inner tie rod end that is covered by a rubber bellow. The inner tie rod end is connected to the outer tie rod end. These rod ends have the ability to move in any linear direction. Finally, the tie rod end is connected to the wheel spindle.

Rack Bellow, Inner Tie Rod, Outer Tie Rod End

Tie Rod End

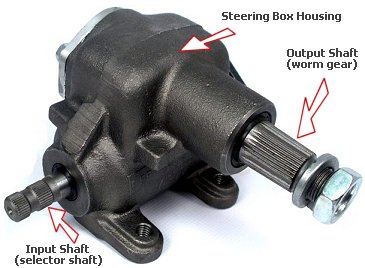

A worm gear box style of steering system is constructed of two main parts much like the rack and pinion style system. The main part is called a worm gear; the other is a selector shaft gear. The worm gear is connected to the pitman arm and then to a center link and tie rod ends. The opposing end of the center link is supported by an idler arm, which is located on the opposite side of the frame from the steering box.

Steering Box (worm)

TESTING POWER STEERING PUMP:

Since there are many variations in power steering pump pressure test procedures and pressure specifications, use your vehicle manufacturer's specific procedures and specifications.

The following is a typical power steering pressure test.

- With the engine stopped, disconnect the pressure line from the power steering pump, and connect the gauge side of the pressure gauge to pump the outlet fitting. Connect the valve side of the gauge to the pressure line.

- Start the engine and turn the steering wheel fully in each direction two or three times to bleed air from the system. Be sure the fluid level is correct and the fluid temperature is at least 176° (80°C). A thermometer may be inserted in the pump reservoir fluid to measure the fluid temperature.

CAUTION

During the power steering pump pressure test with the pressure gauge valve closed, if this valve is closed for more than 10 seconds, excessive pump pressure may cause power steering hoses to rupture, resulting in personal injury.

CAUTION

Do not allow the fluid to become too hot during the power steering pump pressure test. Excessively high fluid temperature reduces pump pressure. Wear protective gloves and always shut the engine off before disconnecting gauge fittings, because the hot fluid may cause burns.

- With the engine idling, close the pressure gauge valve for no more than 10 seconds, and observe the pressure gauge reading. Turn the pressure gauge valve to the fully open position. If the pressure gauge reading does not equal the vehicle manufacturer's specifications, repair or replace the power steering pump.

- Check the power steering pump pressure with the engine running at 1,000 rpm and 3,000 rpm, and record the pressure difference between the two readings. If the pressure difference between the pressure readings at 1,000 and 3,000 rpm does not equal the vehicle manufacturer's specifications, repair or replace the flow control valve in the power steering pump.

- With the engine running, turn the steering wheel fully in one direction, and observe the steering pump pressure while holding the steering wheel in this position. If the pump pressure is less than the vehicle manufacturer's specifications, the steering gear housing has an internal leak and should be replaced or repaired.

- Be sure the front tire pressure is correct, and center the steering wheel with the engine idling. Connect a spring scale to the steering wheel and measure the steering effort in both directions. If the power steering pump pressure is satisfactory and the steering effort is more than the vehicle manufacturer's specifications, the power steering gear should be repaired.

MORE DETAILS FOR WORKING OF POWER STEERING PUMP

Steering can be either power or manual. Power steering utilizes a hydraulic pump mounted on the engine, and driven with a serpentine belt. The fluid in the system is held under pressure until the wheel is turned which releases the pressure and applies it to the steering system. The power steering system fluid should be checked at every service interval. Fluid leaks are a common problem on power steering systems. When a leak is detected inspect the system to determine the course of action, then remove damaged or worn parts and reassemble. Refill system with approved fluid for your particular vehicle. When the power steering system fluid is low a groaning noise will be heard when the vehicle steering is activated. This is caused by the power steering pump scavenging for fluid and taking in air.

A power-steering pump mounted to an engine.

When the engine is off or the system has run completely out of fluid it will be very difficult to steer the vehicle. It is advised not to move a vehicle with power steering when either of these conditions exists. Any steering component malfunction can cause the vehicle to be uncontrollable. All steering components should be inspected for "play" at regular intervals and replaced as needed. When steering components are replaced an alignment is required. Power steering system maintenance is required periodically according to the manufacturer's instructions for your vehicle. Most manufacturers recommend having the hydraulic fluid in the power steering system changed every 60,000 miles.

The opposing end of the center link is supported by an idler arm, which is located on the opposite side of the frame from the steering box. While some road noise is acceptable when driving, a clicking sound is an indication of a component that has failed or has come loose. Many suspension components are in action while the car is driving include shocks, struts, ball joints, lower control arm, bushings, sway bar links and more.

How to Check for Loose Steering System Parts

PARTS:

Mirror

TOOLS

Flashlight

Floor Jack

Safety Tip:

Always wear safety glasses when working on your vehicle. Wear other personal protective equipment (PPE) when necessary, for example latex gloves or closed toe shoes.

1

Secure your vehicle on a level surface, making sure your vehicle will not roll or lean when jacked up.

2

Using a floor jack, lift up the front of your vehicle.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle3

Secure the vehicle with jack stands on both sides for safety before starting any work. The pinch welds or the frame rails are the two best locations. Do not rely on the jack alone to hold the vehicle up while working.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle4

With an assistant wiggling the steering wheel right to left, inspect the steering column, steering box, steering rack and all linkage for looseness.

5

Inspect the outer tie rod ends for excessive play at the connection to the steering knuckle.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle6

If any of the steering system components has looseness or free play beyond the manufacturer's specifications, that component must be replaced.

7

Replace the necessary steering system component and take it to certified technician for proper alignment.

This will help.

Thanks.

cvb

Comments

Post a Comment