How Emission Control System Works?

Emissions

Working Of Emission Control System In Car

Helpful Information

Emission control systems have been incorporated into automobiles to prevent pollution by limiting the amount of partially burned and evaporated gases into the atmosphere. These systems have been efficient in reducing the air pollution caused by automobiles to a large extent. Increased engine efficiency and lighter vehicle construction has also contributed to helping reduce emissions. The different aspects of emissions are tailpipe emissions, life cycle emissions and evaporative fuel emissions.

Unspent fuel vapors are known as the main contributors to air pollution. These omitted gases consist of carbon monoxide, hydrocarbons, carbon dioxide and nitrogen oxide.

Lifecycle emissions are byproducts which are released into the environment during the manufacturing, maintenance and disposal of the vehicle. These products include volatile solvents such as auto paint and lubricants, manufacturing plant waste, petroleum, heavy metals and many more. The name "catalytic converter" was derived from the operation the device performs. A catalyst material converts partially burned gases to completely burned gases.

History

Automobiles were first manufactured with exhaust emissions control systems in 1966. Since then, technology has undergone several advancements that have increased the efficiency of the internal combustion engine. Older emission control systems inject air into the exhaust manifold which are known as, air injection reactor (AIR.) The catalytic converter was developed in the early 1970's when severe air pollution was widespread and was made mandatory by the US government in 1976. An EGR valve is used is to lower KNOX (NO2) gases which occur when the combustion chamber when temperature reaches over 3500°.

Tailpipe emission are measured in parts per million or PPM. The first smog emission test was conducted in the mid 1980's. Restrictions in smog laws came later which ushered in the use of a dynamometer so vehicles could be tested as if they were being driven, the number of gases measured also increased.

Step by step guide on how automotive emissions systems work. This article pertains to all vehicles except electric.

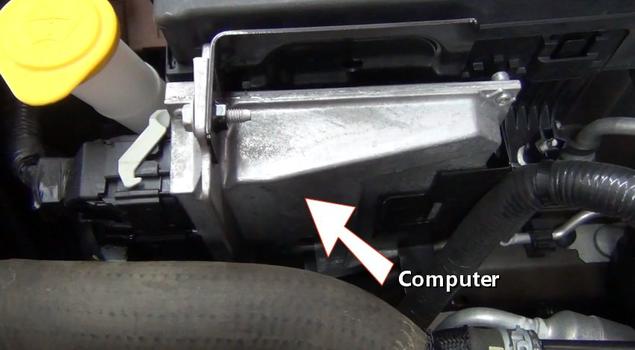

Main Computer

Oxygen Sensor

EVAP Purge Solenoid

Step 4 - An electronic throttle actuator is designed to move the throttle plate only when the engine can utilize the fuel being consumed. This control helps unneeded emissions when a driver over advances the throttle pedal.

Electronic Throttle Actuator

Catalytic Converter

Step 6 - The mass air flow sensormonitors airflow that enters the engine by measuring resistance across a hot wire that is cooled while various amounts of air pass over it. This feedback data trims the computers adjustments to further help clean emission output.

Mass Air Flow Sensor

Step 7 - The gas cap seals the liquid and fumed gases from escaping the fuel tank. This cap is designed with an automatic tightening mechanism to support a minimum tension the cap must be installed at.

Gas Cap

Step 8 - An EGR valve (exhaust gas recirculation) is use to allow engine exhaust to enter the intake manifold of the engine which cools combustion temperatures and lowers emissions.

EGR Valve

Mass Air Flow Sensor

Gas Cap

EGR Valve

Comments

Post a Comment