How A Flywheel - Flexplate Works?

Flywheel - Flexplate

Working Of Flywheel Flexplate

Helpful Information

A flex plate or flywheel is designed with a ring gear on the outer edge which is used by the starter. These units also have the ability to help balance the engine while in operation. A flex plate can fail by forming a crack in the main web of the unit which is accompanied by a chipping or ticking that changes with RPM and engine load.

Standard transmission vehicles utilizes the extra spinning weight a flywheel to help smooth shifting characteristics. A flywheel provides the friction surface for the clutch assembly, this surface along with the clutch pressure plate creates the engagement platform of the clutch.

Step by step instruction on how an automotive flywheel and flex plate works. This article pertains to all vehicles.

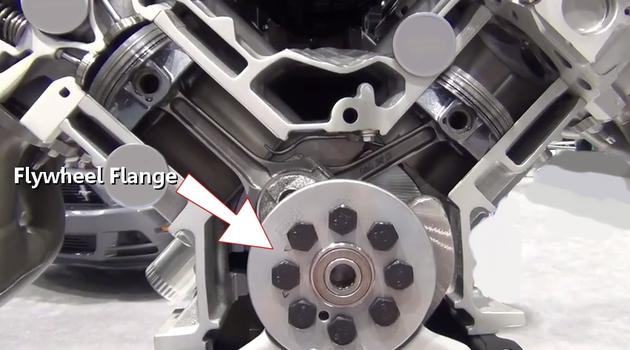

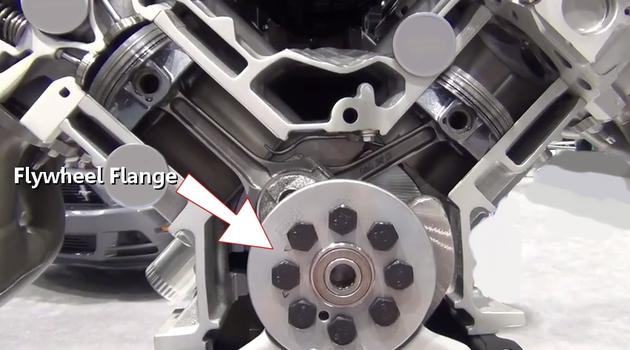

Step 1 - At the rear of every engine is a flywheel flex plate mounting flange in which these units are bolted to. Vehicles equipped with an automatic transmission are typically fitted with a flex plate which is thinner and lighter weight than its counter part, the flywheel which is usually designed for standard transmission vehicles.

Flywheel-Flex Plate Mounting Flange (Block Cutaway)

Step 2 - The flywheel is made of a sturdier design to accommodate the clutch assembly which is used in manual transmission applications.

Flywheel w/Clutch

Step 3 - Hybrid vehicles with automatic transmissions are fitted with a flywheel which is designed to couple the transmission to the crankshaft.

Hybrid Flywheel

Step 4 - The starter is used to turn the flex plate or flywheel to start the engine via the ignition key.

Starter Motor

Flywheel-Flex Plate Mounting Flange (Block Cutaway)

Flywheel w/Clutch

Hybrid Flywheel

Step 4 - The starter is used to turn the flex plate or flywheel to start the engine via the ignition key.

Starter Motor

Comments

Post a Comment