Troubleshooting Car Clutch

How To Fix Car Clutch

Clutch Not Working

Step by step guide on how to fix an automotive clutch assembly that is not working. This article pertains to all vehicles except hybrid and electric.

Difficulty Scale: 4 of 10

Tools and Supplies

Begin with the vehicle on level ground, in park with the engine "OFF". Also apply the parking brake.

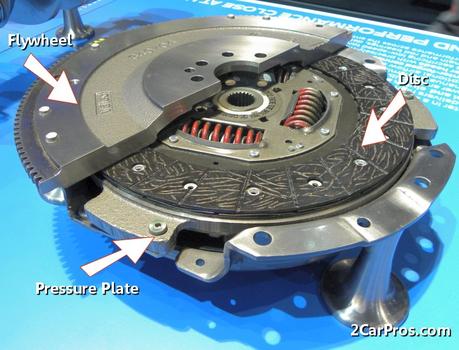

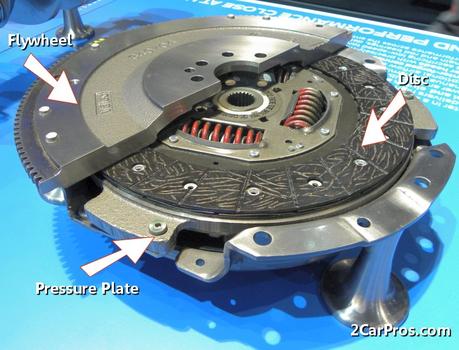

Clutch Cut-Away

Step 1 - A hydraulic clutch systems use fluid to operate the clutch system. Begin by checking the fluid level of the primary cylinder, if the fluid is low or out completely, the system is leaking and repair is required. Inspect the clutch primary and secondary cylinders for leakage at the dust boot of input rods. (Note: inspect under the dash toward the rear of the clutch master where its common for a leak to occur.)

Step 2 - The clutch disc could be completely broken, not allowing the disc to "slip" within the pressure plate and flywheel. The transmission must be removed and the clutch assembly dissembled to inspect for this condition.

Step 3 - The transmission utilizes an input shaft to drive the drive gears inside the transmission. If this input shaft or gears fail, it can cause the gear shifter to move but no output to the differential. The clutch operation will work normally in this condition, the transmission must be removed and be repaired.

Step 4 - If a clutch primary cylinder fails it will not push fluid to the secondary cylinder, in turn not disengaging the clutch disc. To check for this condition have a helper depress the clutch pedal while watching the secondary cylinder, if no movement is observed. the primary cylinder has failed and replacement is required.

Step 5 - Vehicles equipped with a clutch cable use this cable to activate the clutch assembly. If the clutch control cable fails it will not actuate the clutch assembly causing the transmission to not go into gear. If the pedal is depressed with little resistance inspect the clutch cable for failure.

Step 6 - If all clutch actuation methods checks out okay, (cable or hydraulic) and the system still doesn't operate the clutch pivot could have failed. This pivot is used to transfer force from the clutch actuation system to the clutch throw bearing and in turn depress the clutch pressure plate releasing the disc. If this pivot fails it will cause the clutch to not disengage, to check for this problem the transmission will have to be removed in most cases. This condition is rare but it does happen.

Step 7 - The clutch disc is made of an asbestos compound much like a brake pad, when this material wears it loses pressure against the pressure plate and flywheel which allows slippage. The clutch disc is worn out and replacement is needed. (Note: If engine leak are present it can contaminate the clutch disc causing slippage.)

Step 8 - A standard transmission utilizes many roller and thrust bearings to support the shafts and gears which make up the transmission. If any of these bearings fail it will cause the transmission to make a grinding or whirring sound. If a gear synchronizer (synchro) is worn it will not stop the gear when shifting and will cause a grinding inside the transmission when the rotating gears attempt to engage. If either of these conditions has occurred the transmission will have to be replaced or disassembled and repaired.

Step 9 - If the vehicle is running and a whirring sound is heard form the transmission, then it goes away when the clutch is depressed, the transmission input shaft bearing has failed.

Step 10 - If when the clutch pedal is depressed a squealing noise is observed, but quite when the clutch is not disengaged the throwout bearing has failed.

- Flashlight

- Wrench set

- Socket set

- Appropriate replacement parts

- Protective eyewear and gloves

Helpful Information

Never let little clicking noises go unattended; a small noise can cause a large problem. Try not to overload a vehicle or tow beyond the capacity this can cause premature transmission failure.

Best Practices

- When replacing a clutch disc, also replace the pressure plate throwout and pilot bearings if equipped.

- Remove flywheel and have it resurfaced.

- Once the flywheel has been removed inspect the engine rear main seal and replace if needed.

- Always lubricate the throwout bearing slide surface to ensure proper operation

Clutch Cut-Away

Step 1 - A hydraulic clutch systems use fluid to operate the clutch system. Begin by checking the fluid level of the primary cylinder, if the fluid is low or out completely, the system is leaking and repair is required. Inspect the clutch primary and secondary cylinders for leakage at the dust boot of input rods. (Note: inspect under the dash toward the rear of the clutch master where its common for a leak to occur.)

Step 2 - The clutch disc could be completely broken, not allowing the disc to "slip" within the pressure plate and flywheel. The transmission must be removed and the clutch assembly dissembled to inspect for this condition.

Comments

Post a Comment