Air Vents Stay in Defrost Position

Helpful Information

Engine vacuum is used to control the vent position in some vehicles. A simple control valve and vacuum storage tank is used to operate vacuum controlled servos. These servos move various air blend doors inside the air management housing or plenum. Servos are connected to a vacuum source by vacuum hose and utilise a return spring that forces the servo to return when vacuum is not applied. The main engine vacuum is supplied to the control valve on or near the dash. A vacuum check valve is used to stop the flow of vacuum from returning to the engine during low vacuum conditions for example: engine under heavy load like driving up a steep grade. When the engine vacuum supply is lost, the vent control system defaults to the "defrost mode" as a safety precaution. We have listed the most common reasons for this condition below.

Best Practise

- Avoid using tape or glue to repair a vacuum line

Step by step guide on how to repair air vents that stay in the defrost position. This article pertains to vehicles using a vacuum operated heater/air conditioner system.

Difficulty Scale: 3 of 10

Tools and Supplies Needed

- Flashlight

- Protective eyewear and clothing

- Vacuum line

Before you begin, park the car on level ground, with the emergency brake set.

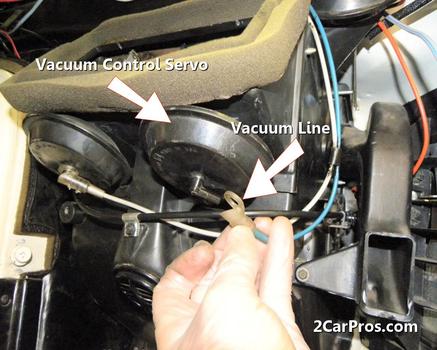

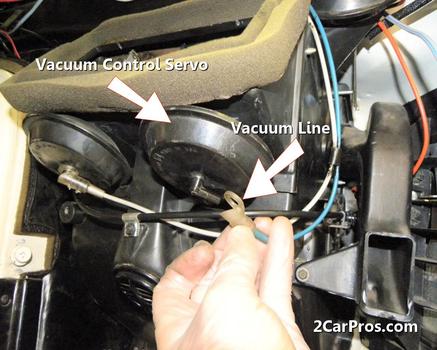

Step 1 - Some heater systems use a vacuum hose that supplies the control valve on the dash with vacuum. This hose can break due to the extreme heat of the engine compartment. Lift your hood and inspect the vacuum hose or tube that leads from the engine intake manifold or vacuum supply manifold to the passenger's side firewall. This hose or tube should be intact and in good working order, if not, repair the hose or tube and recheck system. (After starting the engine give the system a second to react as vacuum fills the system reservoir.)

Vacuum Tube and Control Servo

Vacuum Tube and Control Servo

Step 2 - If you can hear vacuum escaping (hissing sound) from near or around the dash while the engine is running, this means the vacuum supply is escaping. This is a sealed system so if any leak is heard it must be repaired before the system can hold vacuum and operate properly. Usually the vacuum mode control (rotary) switch has failed and needs replacing which is located just behind the temperature control panel.

Step 3 - If the vents move to the defrost position when you are travelling up a hill or under heavy throttle the vacuum check valve has failed and needs replacement. This failed condition allows vacuum to travel from the vent control system back into the engine. To check for this condition locate the system check valve which is located under the hood and remove it. Once the valve has been removed try to blowing through it in both directions. You should be able to only blow through it in one direction, if air flows in both directions the valve has failed and needs replacement.

Comments

Post a Comment