How A Clutch Works

Automatic Transmission Clutch

This article explains how an automotive transmission clutch assembly works.

Helpful Information

When cars were first invented the only option for a transmission was manual (standard.) This gear box was just that a box filled with gears that rotated together while engaging particular gears to different gear ratios. This operation would not be possible without the use of a clutch assembly.

Common Problems

- Clutch slip, which occurs when the clutch disc has worn out and replacement is required.

- Clutch chatter, this occurs when the pressure plate has failed not producing the correct amount of pressure to hold the disc securely.

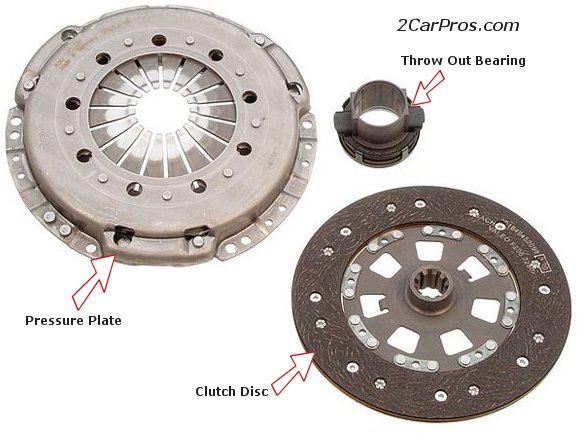

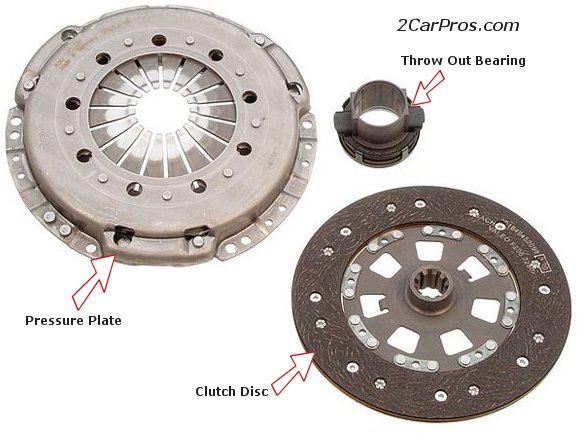

An automotive clutch assembly is used to disengage the engine from the transmission and is comprised of a clutch disc, pressure plate, clutch fork, clutch cable or primary and secondary cylinder, throwout and pilot bearings, (Note: Some front wheel drive vehicles do not use a pilot bearing). A flywheel is used to mount the clutch pressure plate, disc and pilot bearing. The throwout bearing is located on the front transmission bearing retainer. A flywheel is different than a flex plate which do basically the same job, a flex plate is used in automatic transmission vehicles and is thinner and lighter in weight. To activate the clutch a cable or hydraulic system is used to transfer left foot motion to engage or disengage the clutch.

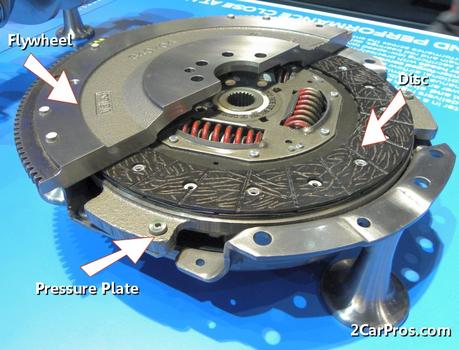

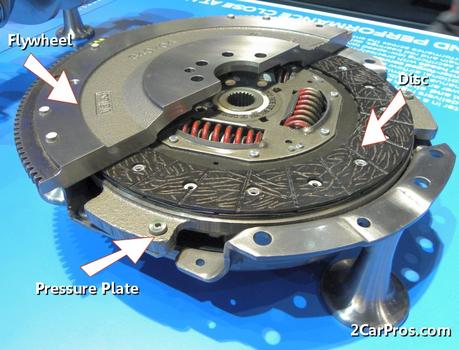

Once the foot lever is activated in transfers motion to the clutch fork which is attached to the throwout bearing. As this mechanism is forced into the pressure plate it releases the clutch disc which is sandwiched under pressure between the flywheel and pressure plate. This allows the the transmission to become disconnected from the transmission input shaft which is connected to the clutch disc. The pilot bearing supports the transmission input shaft and is located at the end of the shaft at the flywheel. Most clutch assemblies operate by holding a clutch disc against a flywheel under pressure with the ability to release the pressure allowing the clutch disc to freewheel. A manual transmission flywheel assembly is made heavier to help engine inertia making shifting smoother.

Clutch and Flywheel Assembly (Cut-away)

When replacing a clutch assembly always resurface the flywheel. As the clutch wears it can cause the flywheel surface to become un-even, much like a worn brake rotor. If a new clutch disc is installed on and old flywheel it can cause the clutch to chatter. If the flywheel is dual stepped (example shown) it must be machined the same way or the clutch clamping pressure will be incorrect causing the clutch to slip or not disengaged. Visit - Clutch replacement and Visit - Clutch failure

Flywheel

There are two different types of clutch activation methods. Some manufacturer's use a cable fastened to a clutch pedal and then to the clutch fork. Others use a hydraulic clutch primary cylinder that is connected to a secondary cylinder which is positioned at the bell housing, also connecting to the clutch fork. When the clutch pedal is depressed it will force the clutch fork onto the pressure plate causing the pressure plate "fingers" to release the clutch disc.

Clutch Pressure Plate, Disc and Throw-out Bearing

Typical Clutch Fork

Standard Transmission

When a throwout bearing starts to fail it can make a chirping noise that is audible when the clutch pedal is depressed or released. If the chirping noise stops or starts suspect this bearing.

Throwout Bearing

Clutch and Flywheel Assembly (Cut-away)

Flywheel

Clutch Pressure Plate, Disc and Throw-out Bearing

Typical Clutch Fork

Standard Transmission

Throwout Bearing

How are you able to tell when the clutch slips? This post said that when it does so, it needs to be replaced, but I don't want to replace it if there may be something wrong with a different part of the engine. Since transmissions can be so temperamental and easily broken, I want to be sure I get it fixed properly before the problem gets even worse. http://www.tyrepowermiami.com.au/contact2

ReplyDeleteThis was a really interesting read! My car is a manual (as was my last one and all my future ones), and so I'm very comfortable with a clutch, but I didn't know how the assembly actually worked. Now I feel much better informed! My clutch is starting to slip, so I'll have to go get my car serviced before my problems get any worse. Is this a relatively simple repair?

ReplyDeleteAdvance Tyre & Auto

I am looking few tips off car accessories & got some useful tips from this post.Thanks for sharing this.

ReplyDeleteVolkswagen Clutch repair & Volvo Clutch repair

With a slipping clutch, you will notice that when you release the clutch pedal, it will take longer for it to engage. Most of the time this is when it's very worn out and by then you should look at getting it replaced. Great source of information here describing everything well. We should know what parts are in each transmission and know the signs of when they are wearing. http://www.rollingbayauto.com/services.html

ReplyDelete