How to test Ignition Coil

Ignition Coil Test

Testing Car Ignition Coil

Tools and Supplies Needed

An ignition system ignites a fuel/air mixture inside the engine's combustion chamber at the optimal moment in the pistons compression stroke. This timing is designed to produce the most power while emitting the least amount of emissions. There are many configurations of ignition systems but all operate on the same principle, create a low energy field and collapse it onto a high energy coil that transfers electrical energy into the secondary ignition system, i.e. coil, wire and spark plug. The system is activated by the primary ignition system, most use a low voltage trigger system i.e. crankshaft position sensor (CKP). This low voltage system (1.0 to 2.0 volts) is increased to 12 volts by using an amplifier which is located inside of the computer or an externally mounted amplifier. The computer PCM (powertrain control module) controls the engine ignition timing by advancing or retarding the primary trigger signal.

- Voltmeter

- Test light

- Socket set

- Wrench set

- Needle nose pliers

- Shop towels

- Protective eyewear and gloves

- Small wire or paper clip

- Screwdriver set

Step by step guide on how to test an automotive engine's ignition coil and trigger, this article pertains to most ignition coil systems.

Difficulty Scale: 4 of 10

Begin with the car on level ground, in park with the emergency brake on.

Step 1 - Identify the type of ignition system to be tested, most cars, use a coil over plug (COP) type of system, there are several variations but all work on the same principal.

Coil Over Plug Ignition System

Step 2 - When checking for a misfire while the engine is still running, the fuel pump must be disabled to avoid accidental ignition discharge. Using the owners manual identify the fuse location.

Fuel Pump Fuse

Step 3 - Once the fuse is located use needle nose pliers or a fuse removal tool to remove the fuel pump fuse from the power distribution center (PDC.)

Removing Fuel Pump Fuse

Step 4 - Remove the safety from the coil electrical connector (red.) Some cars are not equipped with this feature.

Remove Ignition Coil Safety

Step 5 - After the safety has been removed, depress the electrical connector tab to remove the connector from the coil assembly.

Remove Coil Electrical Connector

Step 6 - Once the connector has been removed, located both terminals to be used for testing.

Coil Electrical Connector Terminals

Coil Over Plug Ignition System

Fuel Pump Fuse

Step 3 - Once the fuse is located use needle nose pliers or a fuse removal tool to remove the fuel pump fuse from the power distribution center (PDC.)

Removing Fuel Pump Fuse

Remove Ignition Coil Safety

Remove Coil Electrical Connector

Coil Electrical Connector Terminals

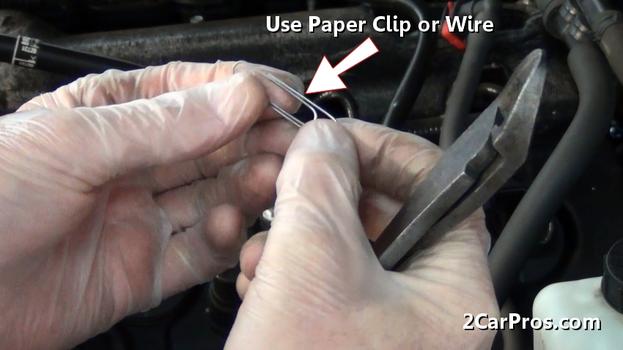

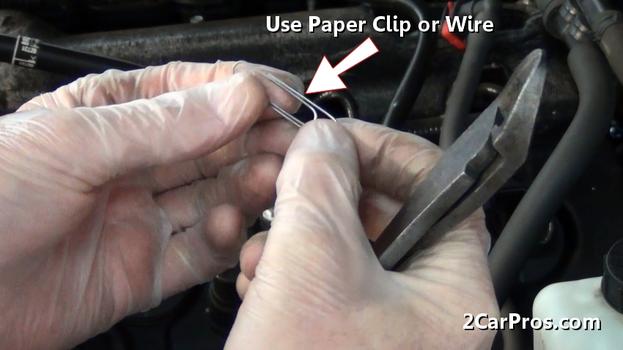

Step 7 - Because these terminals are small in size, sometimes a paperclip or small wire can be inserted into the connector terminals which makes testing easier.

Use a Paper Clip

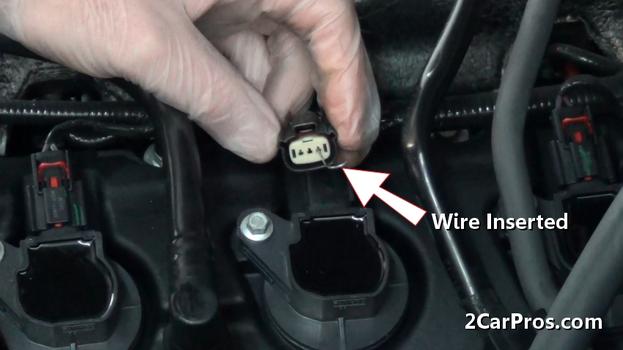

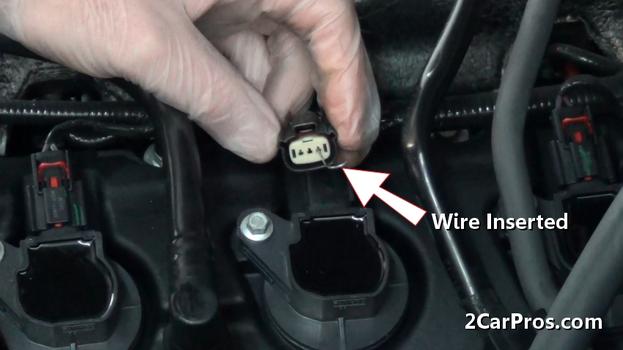

Step 8 - After cutting the paperclip or wire, insert a piece into each terminal, do not allow the wires to contact each other, this could cause damage to the computer.

Wire Inserted Into Connector

Step 9 - Once both terminals have been prepared, use a voltmeter set to the DC voltage setting. Also install alligator clips to the leads to ensure a good connection.

Voltmeter Set to DC Voltage

Step 10 - Next, using the voltmeter lead clips, attach them to the paperclip wires, polarity doesn't need to be observed. (Note: Do not allow the leads to connect during the test.)

Voltmeter Leads Connected

Step 11 - After connecting the leads, turn the ignition key to the "ON" position without cranking the engine. The voltage observed should be 0.

Zero Voltage

Use a Paper Clip

Wire Inserted Into Connector

Voltmeter Set to DC Voltage

Step 10 - Next, using the voltmeter lead clips, attach them to the paperclip wires, polarity doesn't need to be observed. (Note: Do not allow the leads to connect during the test.)

Voltmeter Leads Connected

Zero Voltage

Step 12 - Then, crank the engine over while observing the meter, (engine should not start) the meter should pulsate between 0 and 12 volts. This is confirmation that the computer coil driver is sending signal to the coil for spark and that the ignition system is working. If no voltage is observed while the additional coils on the system operate, check for bad wiring, or computer. If none of the coil triggers operate suspect a crankshaft angle sensor (CKS), or computer control relay.

Pulse Voltage

Step 13 - Once this portion of the test is complete, remove the voltmeter leads and test pins from the coil electrical connector.

Removing Meter Leads

Step 14 - With the electrical connector disconnected, remove the ignition coil mounting bolt.

Removing Ignition Coil Mounting Bolt

For Further instructions Click Part 2

Pulse Voltage

Removing Meter Leads

Removing Ignition Coil Mounting Bolt

Comments

Post a Comment