How To Replace Brake Master Cylinder

BRAKE MASTER CYLINDER REPLACEMENT

Customers Noticed Problems With Brake Master Cylinder Also Asked Such Questions

how to fix a master cylinder?

how to check master cylinder?

bench bleeding master cylinder?

brake master cylinder repair?

how to check your master cylinder?

brake master cylinder test?

master cylinder repair?

how to bench bleed a brake master cylinder?

What common symptoms indicate you may need to replace the Brake Master Cylinder?

How do you know if you need a new master cylinder? Most of the time, if a brake component needs replacing, it leaves a trail to follow. This trail is made of stinky brake fluid. That's the good news. Following a trail of brake fluid will usually lead you to a current or future brake problem. There are lots of brake components that can go bad. You've got wheel cylinders, master cylinders, discs, boosters, ABS systems and even brake pads.

- Brake warning light is on.

- Brake fluid leak (clear fluid on the ground or under the brake pedal inside the car.)

- Soft brake pedal (pedal goes all the way to the floor when pushed).

Step by step guide on how to replace a brake master cylinder, This article pertains to most cars.

How it's done:

Inspect brake master cylinder for leaks.

Inspect brake booster.

Remove and replace the brake master cylinder if faulty.

Change the brake fluid.

Bleed entire brake system of air.

Clean brake fluids from all the wheels.

Perform brake safety inspection.

- Replacement brake master cylinder

- Brake fluid

- Line wrench set

- Show towels

- Socket set

- Protective gloves and eye wear

Brake Master Cylinder Replacement Service & Cost

What is the Brake Master Cylinder all about?

The brake master cylinder contains brake fluid and is connected to the brakes through the brake pipes and hoses. When you step on the brake pedal, brake fluid flows from the master cylinder to the braking unit at each wheel, creating enough friction to slow down and/or stop the car. The brake master cylinder has internal and external seals that can wear out over time.

If the external seals have worn out, they will leak brake fluid, reducing the amount of fluid in the car and causing the brakes to malfunction. Worn external seals can also leak the fluid into the brake booster and destroy it. The brake booster is essential for the proper functioning of the brakes, so if brake fluid has leaked into it, replacement is required.

If the internal seals have worn out, the brake fluid will continue to circulate inside, instead of being directed to the brakes. This weakens brake performance. The brake pedal will feel soft. When you apply the brakes, the pedal will go all the way to the floor without significantly slowing down or stopping the car.

After replacing the brake master cylinder, the mechanic should flush the old brake fluid out and replace it with new brake fluid.

If you think you need to replace your master cylinder, check out our brake troubleshooting checklist to be sure. If you're sure, read on and we'll walk you through the process. It's not bad at all.

Brake Master Cylinder

Brake Fluid RemovalStep 2 - Remove the electrical connector to the fluid level sensor. Most connectors have safety clips that need to be released before they will disconnect.

Removing Brake Fluid Warning Light Connector

Removing Brake Fluid LinesStep 4 - Insert socket wrench onto master cylinder mounting bolts. After mounting bolts are removed, lift the master cylinder off the mounting studs and out of the vehicle.

Brake Master Mounting Bolts

Reinstall New Brake Master Cylinder

Helpful Information

- Master cylinder fails, illuminating the brake warning light.

- Master cylinder leaks fluid, illuminating the brake warning light.

- Master cylinder actuator rod is adjusted out too far, not letting the brake master plunger to return creating residual brake pressure causing the brakes to drag.

- Always use brake fluid from a closed container to avoid moisture contamination.

- Check brake shoe adjustment (drum brakes only).

ALSO GO THROUGH GUIDE NUMBER 2

Safety Tip:

Always wear safety glasses when working on your vehicle. Wear other personal protective equipment (PPE) when necessary, for example latex gloves or closed toe shoes.

3/3

3/3

4/3

4/3

Always wear safety glasses when working on your vehicle. Wear other personal protective equipment (PPE) when necessary, for example latex gloves or closed toe shoes.

1

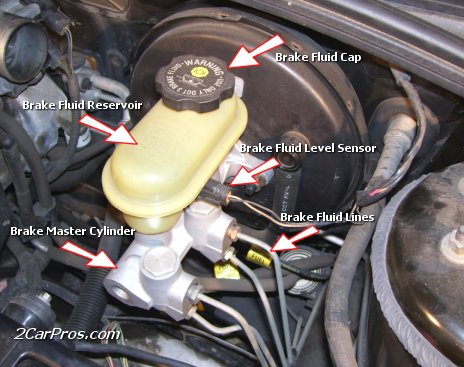

Open hood and locate the vehicle brake master cylinder.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

2

Inspect brake fluid level. Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

3

Using a turkey baster, withdraw the brake fluid from the master cylinder.

4

Remove the brake lines from brake master cylinder using flare nut wrenches.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

5

Disconnect any electrical connectors from the brake master cylinder.

6

Unbolt the brake master cylinder from the brake booster or from the firewall.

7

Mount new brake master cylinder in a vice.

8

Fill both chambers of the brake master cylinder reservoir with clean (new) brake fluid.

9

Using a bench bleeding kit thread the adaptors into the brake master cylinder.

10

Route the tubing back into the brake master cylinder reservoir chamber(s).

11

With a Phillips screwdriver, slowly pump the piston using full strokes.

12

Keep pumping the brake master cylinder until all the air is removed (no more bubbles noted). Keep the master cylinder reservoirs filled during this step.

13

Install the new brake master cylinder to the brake booster.

14

Remove bench bleeding fitting and install brake lines. Some brake fluid may leak out but the brake master cylinder should stop any major leak.

15

Fill the master cylinder reservoir with clean (new) brake fluid of the correct type.

16

Secure your vehicle on a level surface, making sure your car will not roll or lean too much when jacked up.

17

Lift up your vehicle with a floor jack.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

18

Secure the vehicle with jack stands on both sides for safety before starting any work. The pinch welds and the frame are the two best locations. Do not rely on the jack to hold the vehicle up while working.

19

Remove the wheels by removing the lugs nuts that are holding them on. To do this you will need to find the correct size socket and large ratchet or tire iron and turn them counter clockwise. If your vehicle is equipped with hub caps (plastic covers over the wheels), these will need to be removed to access the lug nuts.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

20

Place a 1 x 4 block of wood under the brake pedal to prevent the pedal from traveling too far.

21

Locate the brake bleeder valve on your passenger side rear brake caliper or wheel cylinder - the position furthest from the master cylinder.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

22

Install a piece of clear plastic tubing over the brake bleeder valve screw and place the other end into a container half full of brake fluid.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

23

Have your assistant slowly depress and hold the brake pedal down.

24

Crack the bleeder valve open. Old fluid and air bubbles will travel down the clear tubing and into the container. Tighten the bleeder valve.

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

Photo may not be specific to your vehicle

25

Repeat this process until clean fluid comes out of the bleeder valve and there are no more air bubbles. Check and refill the master cylinder with clean (new) brake fluid of the correct type. Do not allow the master cylinder to drain completely.

26

Repeat steps 22 through 25 in the following order: Left rear wheel, right front wheel, left front wheel.

27

Reinstall wheels, lower the vehicle to the ground and verify the repairs with a road test.

Brake System How-To

Bench Bleed a Master Cylinder

Making our cars go fast is an exciting part of our hobby. Making 'em stop is usually not so exciting--that is unless you've experienced your quickest pass ever, only to discover that spongy pedal may not get you stopped in time. Many forward-thinkers realize the importance of good brakes and perform upgrades to attain this.

How to Check Your Brake System's Master Cylinder.

Essentially, when you check your master cylinder, you’re making sure that you have enough brake fluid, which is stored in the master cylinder. When you step on the brake pedal, fluid goes from the master cylinder into the brake lines; when you release the pedal, the fluid flows back into the master cylinder.

To check the brake fluid in your master cylinder, follow these steps:

Giving proper attention to your brake system is vital. Many times the correct bench bleeding of the master cylinder is an overlooked task. However, this is a MUST and should be performed any time a new master cylinder is installed. If the master cylinder is not bled, it will take you at least twice as long to bleed the system, and then there's no guarantee that you'll have removed all the air from the system.

Open the brake fluid reservoir on top of your master cylinder.

If you have the kind with a little plastic bottle on top, just unscrew the cap on the little plastic bottle that sits on top of the master cylinder. If you have a metal reservoir, use a screwdriver to pry the retaining clamp off the top.

Don’t let any dirt fall into the chambers when you open the lid. If your hood area is full of grime and dust, wipe the lid before you remove it.

Before bench bleeding the master, completely install all of your replacement or upgraded brake components, including the master cylinder and brake lines; this is so you can hook up the master cylinder as soon as possible after it has been bench bled, to keep gravity from leeching fluid from the master cylinder during the installation of the other components. After installing the system, remove the master cylinder completely from the vehicle. Master cylinders MUST be bench bled outside the vehicle and without any other components attached. This means that if a new master is equipped with a booster, proportioning valve and plumb lines attached, they must all be removed prior to bench bleeding.

Take a look at the lid.

As the brake fluid in your master cylinder recedes (when it’s forced into the brake lines), the diaphragm cups are pushed down by air that comes in through vents in the lid. The cups descend and touch the surface of the remaining brake fluid to prevent evaporation and to keep the dust and dirt out. When the fluid flows back in, the cups are pushed back up.

If your brake fluid level is low, or if the cups are in their descended position when you remove the lid, push them back up with a clean finger before you replace the lid.

Be sure to place the master cylinder level in a vice and secure it properly. If the cylinder isn't level, not all the air will be able to be removed from the master cylinder. Remove the master cylinder top and fill with fresh brake fluid to the appropriate level as indicated in the master cylinder-- generally about 1/2 to 1 inch from the top of the reservoir.

Insert a pair of short, looped brake lines or rubber tubing from a bench bleeding kit, (available at nearly all auto parts stores), into the two side ports of the master cylinder. (Note: on dual-ported master cylinders where there are four ports, choose one side and use both ports on that one side to perform the bleed process.) Insert one rubber tube into each of the plastic fittings. and the loose ends should be inserted into the master cylinder reservoir. The plastic tab should be used to hold the tubes in place by slipping it over the reservoir separator and the hoses through the round holes.

Look inside the master cylinder.

The brake fluid should be up to the “Full” line on the side of the cylinder or within 1⁄2 inch of the top of each chamber. If it isn't, buy the proper brake fluid for your vehicle and add it until the level meets the line.

Close the brake fluid reservoir as quickly as possible so that oxygen or water vapour in the air doesn't contaminate the fluid. And try not to drip it on anything; it eats paint!

Using a wooden dowel, a blunt metal rod, or a large Philips screwdriver, compress the master cylinder plunger with slow, deep strokes. Once the large bubbles have subsided, it should become increasingly more difficult to compress the master cylinder piston. Continue to do so with slow, short strokes at the bottom of the piston stroke until no more bubbles appear. The rubber hoses and plastic fittings may be removed from the master cylinder. Secure the master cylinder top, install the master cylinder and leave enough room on the mounting nuts to allow for some movement of the master. This will allow you some breathing room while screwing in the hydraulic lines to help prevent cross-threading the fittings.

If both chambers of your master cylinder are filled with brake fluid to the proper level, close the master cylinder carefully, without letting any dirt fall into it.

Because most master cylinders are pretty airtight, you shouldn't lose brake fluid in any quantity unless it’s leaking out somewhere else.

Use a flash-light to look for stain marks, wetness, or gunk under the master cylinder.

If your master cylinder is — or has been — leaking, you’ll see evidence of it when you look closely.

It’s a good idea to check your master cylinder at least every couple of months — more often if it was low in fluid when you last checked it.

What could prevent enough pressure in a replaced master cylinder on a Hyundai Tucson to bleed the brakes?

Case details: The front and rear pads and rotors were also replaced.

This typically happens when air enters the ABS hydraulic unit. The pump motors will need to be actuated to drive the air out, but to do this a scan tool will have to be used. There is another alternative without the need for a scan tool which has a 70% success rate. Hoist the vehicle and rest it on jack stands so all 4 wheels are off the ground. Start the car, engage gear and accelerate till the speedometer reaches about 20 mph. Now hit the brake pedal about 15-20 times which normally should be enough to actuate the ABS motors. Leave the engine to idle and begin the bleeding process. The correct sequence to follow is right rear, left front, left rear and right front. Once done, test the pedal which should offer firm resistance. If it does, the bleeding process has been successful; if not there is no option but to resort to a computerized bleeding technique.

What causes a Hyundai Elantra brake pedal to feel spongy with no master cylinder issues?

One possibility is that the caliper slides are bad and bend when the brake pedal is pushed down which will create a low, spongy feel. But the problem should be properly diagnosed. To do this clamp off the hoses to all brake lines near each wheel. Now start the vehicle and check if the pedal is firm. If it is not, then the master cylinder is bad and needs to be replaced or there is air in the system which needs to be bled. If the pedal is firm then release the clamps one at a time followed by a press on the pedal to see if there is any difference. If there is problem and its in the front wheel then the calipers might need to be replaced as one caliper slide might be sticking causing the other to bend under pressure. If the rear wheels are at fault then something might have broken or gone out of adjustment.

Why does an Elantra not stop fast enough though the master cylinder, rotors, pads and calipers have all been changed?

If everything has been checked then the brake proportioning valve, which most cars have, is possibly faulty. However, if this vehicle does not have a proportioning valve and, assuming the calipers and everything else is good, then it could be a bleeding problem. Bleeding the braking system of this car has to be done with a scan tool by someone experienced. Furthermore, the manufacturer has prescribed a sequence that has to be followed which a surprising number of technicians are unaware of. If bleeding is not done properly effective braking is consistently and seriously compromised.

Will the master cylinder, with new calipers, pads and lines on a Sonata cause all four wheels to consistently lock up?

This is a typical indication that the brake master cylinder is not releasing and has failed. The only repair solution is to replace the master cylinder.

Why does a Hyundai clutch not release at times and prevent the gear from shifting?

This is symptomatic of a bad clutch master cylinder or slave cylinder. Often it might be accompanied by a strange sound whenever the clutch is depressed which generally comes from the linkage. There might also be signs of fluid leakage or wetness around the master cylinder. Replacement is the solution.

Will the master cylinder cause the clutch to have to be pumped several times before a Tiberon can be moved into gear?

The clutch master cylinder needs to be replaced because in all probability it is leaking internally. There may or may not be external signs of leakage but nonetheless it is faulty. After installing a replacement, the system will have to be properly bled. Care should be taken to ensure that the master cylinder push rod is properly adjusted especially if an aftermarket part is used.

Will the master cylinder cause the clutch to burn out on a newer Hyundai i10?

It could be that the master cylinder was not properly adjusted at the factory and so kept the clutch always slightly engaged which has resulted in premature wear. It might be an idea to contact the corporate office and advise them of your bad experience and displeasure.

Because of their sustained use, problems do arise with master cylinders and their operation which could have serious consequences if not properly identified and resolved in a timely manner. In such situations, an owner will benefit from asking a verified mechanic for advice. Experts are always available to answer your questions regarding the master cylinder.

Comments

Post a Comment